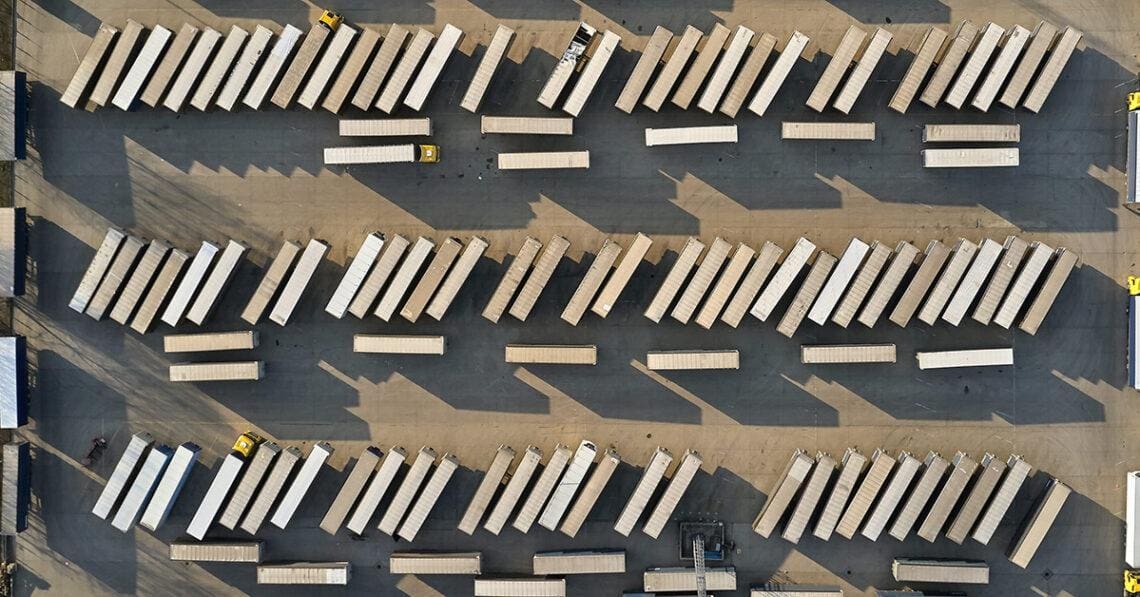

Manufacturers are pressed from all sides to prove their environmental bona fides, but given the nature of manufacturing-related emissions, that means making sure their global supply chains are environmentally conscious. Assent’s Sarah Carpenter digs into her company’s recent survey of manufacturers, the pressures these companies are facing and what they can do about it.

ESG-related investment is soaring, business is assessing its impact on the environment, and regulators across the globe are pressuring firms of all types to make ESG issues a top priority. But getting their arms around environmental impact is easier said than done, particularly for manufacturers. According to a McKinsey study, only about 5% of greenhouse-gas emissions (GHG) for manufacturing companies come from direct emissions, while about 85% are buried in supply chains.

As sustainability continues to take its place as an essential part of doing business, Assent surveyed the manufacturing industry on the state of their ESG manufacturing programs and maturity.

Key findings of “The State of ESG in Manufacturing” include:

- 76% of manufacturers are at the planning or foundational stages of supply chain ESG maturity.

- 80% say their organizations are somewhat to extremely dependent on partners and suppliers to help them achieve supply chain sustainability/ESG goals.

- 59% expect this dependency on their partners and suppliers to increase in the next year.

- 31% said they are highly confident in the quality and accuracy of their organization’s supply chain data.

What does this mean for manufacturers as they look toward growing their ESG programs? Both market due diligence drivers and regulatory changes must be top of mind as we enter 2023.

Only 1 in 4 Manufacturers Have High Confidence in ESG Readiness of Their Supply Chains, Survey Finds

Ever-evolving regulatory requirements, consumer demand and investor expectations are all forcing manufacturers to increase the transparency of their supply chain, but few organizations have arrived at that destination, according to a new survey by SaaS supply chain provider Assent.

Read moreDetailsMarket drivers

Market pressure to align with industry-standard ESG practices is strong, and it’s only going to increase. In our study, respondents cited a variety of market pressures:

- 39% said environmental concerns were driving their ESG programs.

- 33% noted customer demand led to more ESG investment.

- 27% see ESG programs as the key to a more resilient supply chain.

Investors now see manufacturers with low ESG maturity levels as risky investments. They don’t want the financial risk associated with a portfolio company’s regulatory penalties, nor do they want the reputational damage when one of their investments makes the headlines for human rights violations or environmental harm.

Customers also want to buy from suppliers with good ESG records, and so manufacturers are responsible for their suppliers’ actions. Pressure from customers has become so great that some manufacturers can’t compete for requests for proposals without demonstrating a strong ESG record.

Regulatory drivers

On the compliance side, there are a number of regulations putting greater pressure on manufacturers to gather and report on ESG data from their supply chain.

The Uyghur Forced Labor Prevention Act

The U.S. Uyghur Forced Labor Prevention Act (UFLPA), which came into effect in June 2022, says that any goods mined, produced or manufactured, wholly or in part, in the Xinjiang Uyghur Autonomous Region (XUAR) of China are presumed to be made with slave labor and thus can’t enter the U.S. unless the importer can prove otherwise.

In the first six months the UFLPA was in effect, U.S. Customs and Border Protection targeted 2,692 shipments valued at over $817 million for suspected links to the XUAR. As UFLPA enforcement is a priority for the CBP, these numbers will only increase in the coming years.

The German Supply Chain Due Diligence Act

At the beginning of this year, the German Supply Chain Due Diligence Act (SCDDA) — also known as Lieferkettensorgfaltspflichtengesetz in German — came into force. The SCDDA requires companies to perform due diligence on such human rights and environmental risks as:

- Child labor.

- Forced labor.

- Products containing added mercury.

- The import and export of certain hazardous waste.

Until the beginning of 2024, the scope of this law applies to companies in Germany (even if they only have a branch office) with 3,000 employees or more. At the beginning of 2024, that scope will expand to companies with 1,000 employees.

SCDDA violations could lead to significant fines and exclusion from public procurement opportunities.

The EU Corporate Sustainability Reporting Directive

In January, the Corporate Sustainability Reporting Directive (CSRD) entered into force for companies with operations in Europe. The CSRD amends the Non-Financial Reporting Directive (NFRD) to improve the reliability, relevance and comparability of ESG data.

Under the CSRD, in-scope companies will have greater reporting obligations, and more companies will be in-scope. More than 11,000 companies are currently in scope of the NFRD, while the CSRD will apply to nearly 50,000 businesses.

Proposed legislation

In addition to measures already passed and implemented, there are three major regulatory and legal requirements in the works that are likely to affect manufacturers:

- The SEC’s climate disclosure rule, which would enhance and standardize climate impact disclosures from publicly traded companies.

- The EU ban on goods made with forced labor, which covers all products imported or manufactured in the EU.

- The EU Corporate Sustainability Due Diligence Directive (CSDDD), which would introduce human rights and environmental due diligence requirements on EU and non-EU companies.

Strengthening ESG programs

Many manufacturers lack confidence in their supply chain data. However, our study found nearly three-quarters of survey respondents want to invest more in their sustainability programs in the coming year. How can they do that effectively?

There are four best practices:

Supplier education

Suppliers are less likely to provide reliable supply chain data if they don’t understand their requirements, why clients are asking them for specific data and how this data helps their clients achieve compliance. Educating suppliers on these topics enables them to give manufacturers the data they need for ESG compliance.

Reducing supplier fatigue

The acceleration of ESG programs means manufacturers will send more and more surveys and corrective action plans to suppliers asking them for ESG data and to engage in an improvement journey. That can create supplier fatigue, which means they’ll ignore surveys and follow-up actions, so manufacturers won’t get the data and the risk mitigation they need.

By sending out standardized surveys such as the industry-standard Slavery and Trafficking Risk Template (STRT) and collaborating with other manufacturers using a common platform, manufacturers streamline the process for suppliers.

Speaking suppliers’ language

The global nature of complex manufacturers’ supply chains means suppliers often speak another language — chances are it’s not yours. Communicating with suppliers in their own language increases the chances they will provide manufacturers with essential ESG data, so it’s crucial to have adequate translation abilities.

Framing sustainability as a journey

Telling suppliers that their low ESG score puts manufacturers at risk of losing their commercial relationship does not build a trusting partnership. Instead, frame sustainability as a journey whereby the core expectations are transparency and continuous improvement.

Improving ESG maturity

Only 25% of respondents have high confidence that they can currently reach their goals with the partners in their supply chain.

But there is a way forward, as we see over two-thirds of respondents expecting investments in ESG/sustainability to increase. Low ESG maturity represents an opportunity.

Companies that are in the early stages of developing their ESG program are far from alone. Improving ESG practices will not happen overnight. Suppliers will need manufacturers’ support and guidance. Pressures will differ for manufacturers based on where they are in the ecosystem. However, what remains consistent is that all manufacturers face these pressures — and they’re not going away.

Sarah Carpenter is director of corporate responsibility at Assent. Sarah provides direction to Fortune 500 companies on human rights due diligence and ESG strategies with a focus on supply chain impacts. She also leads Assent’s B-Corp Certified corporate sustainability program. Following the 2013 Rana Plaza collapse in Bangladesh, she supported the United Nations International Labour Organization’s work promoting labor rights reform in the garment industry. Sarah has worked for a range of rights-based non-governmental organizations, including Plan International and the Canadian Network on Corporate Accountability. She is the current chair of the Slavery and Trafficking Risk Template Working Group of the Social Responsibility Alliance.

Sarah Carpenter is director of corporate responsibility at Assent. Sarah provides direction to Fortune 500 companies on human rights due diligence and ESG strategies with a focus on supply chain impacts. She also leads Assent’s B-Corp Certified corporate sustainability program. Following the 2013 Rana Plaza collapse in Bangladesh, she supported the United Nations International Labour Organization’s work promoting labor rights reform in the garment industry. Sarah has worked for a range of rights-based non-governmental organizations, including Plan International and the Canadian Network on Corporate Accountability. She is the current chair of the Slavery and Trafficking Risk Template Working Group of the Social Responsibility Alliance.